LCD Refurbishment

LCDREFURB main activity is the refurbishment of broken tablets and smartphones LCDs.

iPhone LCDs represent 75% of our business and all the refurbishing process is made in house.

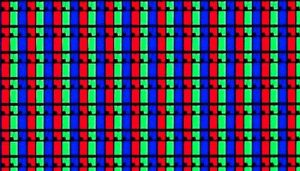

iPhone LCDs use a technology called Retina Display or IPS (In-plane switching).

The original screens produced for Apple products are 1st choice components, hence why a refurbished original screen is superior in quality to all Chinese copy LCDs you can find on the market.

Quality means doing it right when no one is looking.

'Quality is not act. It is a habit.

iPhone LCDs represent 75% of our business and all the refurbishing process is made in house.

iPhone LCDs use a technology called Retina Display or IPS (In-plane switching).

The original screens produced for Apple products are 1st choice components, hence why a refurbished original screen is superior in quality to all Chinese copy LCDs you can find on the market.

Refurbishing a screen consist in replacing the broken glass and the frame in a broken screen. We do not modify the quality of the original LCD.

For example, we do not use LOCA glue to attach the new glass to your screen which diminish the touch screen responsive uniformity, we use 3M Double coated 1 mil Optical Clear Adhesive (OCA) in our clean rooms.

The backlight is very often damaged on your old iPhone screen, liquid damage, temperature or simply age. We replace the backlight using original LED backlight, they are generally a bit more expensive than their Chinese counterparts, but gives the best results. Your screen displays the same colors as a brand new screen. Backlighting is performed in house by our trained engineers, we do not use any third party.

The laminating process is very important in the refurbishing process, it consists in “gluing” the new glass and touch screen to the refurbished LCD. To ensure maximal results we are using automatic bubble free vacuum laminator in our clean rooms. The new touch screens are attached with our 3M OCA to the LCD without any bubble, we do not use any autoclave like most of the refurbishing companies. Our laminators machines are the most advanced on the market, not the sub 5K machines products you can find online. It ensures the plastic is not outgassing. Substrates tend to absorb moisture and outgas when exposed to high temperature and high humidity, creating bubble defects in laminated parts.

LCDREFURB is now refurbishing Samsung smartphone LCDs too, the Samsung LCDs are very different from the iPhone LCDS, they use a different technology called AMOLED.

Typically Samsung refurbishing screens consisted of replacing a broken glass using LOCA glue and a new touch screen. That’s a very fast and inexpensive way to fix a Samsung screen, but the quality is quite poor and amateurish.

Samsung screens are very expensive and deserves better than a simple LOCA replacement glass. So, we adapted our effective and winning IPS iPhone technic to Samsung screens.

We replace the frame on all Samsung LCDs, so your refurbished screens looks really like new and we use 3M OCA to attach your new touch screen for maximum responsiveness.

With the introduction of curved screens our team had to develop new technics and challenging hardware equipments like Nitrogen liquid and 3D printing moulds. The results are mind blowing and our customers are saving thousands of pounds on their Samsung repairs.